Phone:

TBA

Physical address:

TBA

Understanding scaffolding load capacity is crucial for safety and efficiency on construction sites. It helps prevent accidents by ensuring you don’t exceed the weight limits. Calculating the combined weight of workers, tools, and materials is essential. Know that light-duty scaffolds support up to 25 pounds per square foot, medium-duty handles up to 50 pounds, and heavy-duty supports up to 75 pounds. Always factor in a safety margin of 25-50%. Regular inspections and adherence to manufacturer guidelines are vital for safe use. There’s more to ensuring safe scaffolding practices, so stay informed to keep working safely, especially regarding scaffolding safety.

Understanding the importance of load capacity in scaffolding ensures safety and efficiency on construction sites. When you’re working at heights, knowing exactly how much weight your scaffolding can bear is crucial. It prevents accidents that could lead to injuries or even fatalities. Overloading scaffolding can cause it to collapse, putting not only workers but also the public at risk.

You need to calculate the combined weight of workers, tools, and materials to avoid exceeding the scaffolding’s load capacity. This calculation isn’t just a good practice; it’s often a legal requirement. Building codes and regulations usually specify maximum load limits for scaffolding. Ignoring these rules could result in hefty fines or project shutdowns, which no one wants.

Moreover, understanding load capacity helps you plan your work more efficiently. When you know the limits, you can organize tasks to ensure that the scaffolding is used within its safe capacity. This foresight minimizes downtime caused by the need to constantly check and recheck the scaffolding’s stability, thereby promoting safer construction work.

Additionally, proper load management extends the lifespan of your scaffolding. Regularly overloading it can weaken the structure over time, leading to more frequent repairs or replacements. By adhering to load capacity guidelines, you’re investing in the long-term durability of your equipment. Go back to Scaffold for Hire Home Page.

When considering scaffolding, you’ll encounter various types, each with its unique load capacities and uses. It’s important to calculate the load capacity to ensure safety. Supported scaffolding comes in multiple forms, ideal for different tasks and environments. Additionally, suspended scaffolding offers alternatives for working at height, often used in construction and maintenance projects.

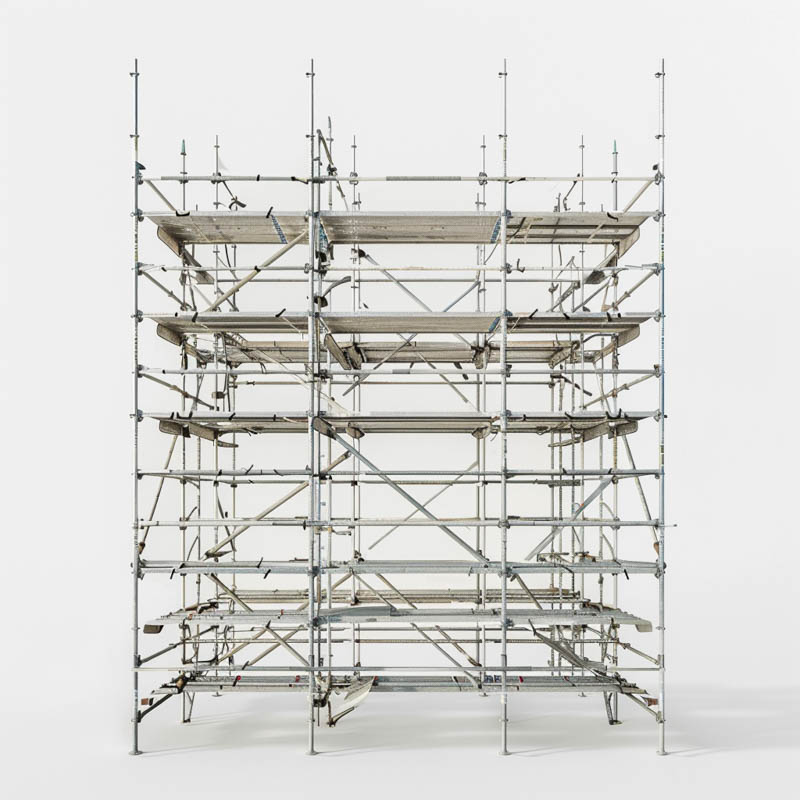

Among the various supported scaffolding types, each serves specific purposes and offers distinct advantages for different construction work needs. Frame scaffolding is one of the most common types you’ll encounter. It’s easy to assemble and disassemble, making it a favorite for many construction projects. This type of scaffolding consists of welded steel or aluminum frames, which can be stacked to reach desired heights.

Another popular type is system scaffolding. This variation is known for its versatility and strength. It’s composed of prefabricated components that connect systematically, providing robust support for complex structures. System scaffolding is often used in large-scale construction projects where high load capacities are crucial.

Lastly, there’s mobile scaffolding, which offers the advantage of mobility. Equipped with wheels, this type can be easily moved around, making it ideal for tasks requiring frequent repositioning. Mobile scaffolding is perfect for indoor projects and maintenance work.

Understanding these supported scaffolding variations ensures you choose the right type for your project’s specific requirements.

Unlike supported scaffolding, suspended scaffolding hangs from an overhead structure, allowing workers to access hard-to-reach areas with ease. There are several types of suspended scaffolding you might encounter, each serving different purposes based on the job requirements.

One common type is the two-point adjustable scaffold, often called a swing stage. It’s suspended by ropes or cables from an overhead support and can be raised or lowered to the desired height. This system is often used in heavy-duty scaffolding. You’ll often see this type used by window washers on tall buildings.

Another type is the single-point adjustable scaffold. This system is also suspended by ropes or cables, but it features a single point of suspension. It’s ideal for smaller, more confined areas where a broader platform isn’t necessary.

Catenary scaffolding is another option, where the scaffold platform is supported by horizontal and vertical ropes forming a net-like structure. This type is particularly useful when working on surfaces with varying heights.

Finally, multi-point adjustable scaffolding consists of platforms suspended by multiple ropes. This type offers greater stability and is suitable for larger projects requiring more extensive coverage.

Understanding these types will help you select the right scaffolding for your project’s unique needs, ensuring safety and efficiency.

Understanding the factors affecting scaffolding load capacity is crucial for ensuring both safety and efficiency on construction sites. If you’re setting up scaffolding, you’ll need to consider several key elements that can impact how much weight your scaffolding can safely support. Overlooking any of these factors can lead to dangerous conditions and potential accidents.

First and foremost, the material of the scaffolding plays a significant role. Different materials like steel, aluminum, or wood have varying strength and flexibility properties. Steel scaffolding, for instance, tends to have a higher load capacity compared to aluminum. So, always check the manufacturer’s specifications for the material you’re using.

Another critical factor is the design and construction of the scaffolding. Well-constructed scaffolding will distribute weight evenly, reducing the risk of collapse. Ensure that all parts are properly assembled and that the structure is stable. Pay attention to the bracing, fastening, and spacing of the scaffold components.

Lastly, environmental conditions can’t be ignored. Wind, rain, and even temperature can affect the load capacity. Wet or icy conditions can make scaffolding slippery, increasing the risk of falls and shifting weights. Strong winds can also sway the scaffolding, putting additional stress on the structure.

Here are some key factors to keep in mind:

When calculating load capacity, you’ll need to determine the weight limits for your scaffolding. It’s crucial to include a safety margin to ensure the structure can handle unexpected loads. Let’s break down these key points to help you make accurate calculations.

To accurately calculate a scaffold’s load capacity, you need to consider the combined weight of workers, tools, and materials. Start by figuring out the maximum number of workers who’ll be on the scaffold at any given time. Average the weight of these workers to get a total. Next, estimate the weight of tools and materials they’ll be using. This includes everything from power tools to buckets of paint. Don’t forget to factor in any dynamic loads, like the force exerted when workers move or shift materials.

Here are some key steps to guide you in scaffolding safety:

After determining the total load, it’s important to incorporate a safety margin to ensure the scaffold can handle unexpected stresses. This margin acts as a buffer against unforeseen weight increases or dynamic forces that might occur during use. To calculate it, you’ll typically add 25-50% to your total load. For instance, if your scaffold’s total weight limit is 1,000 pounds, incorporating a 25% safety margin means it should support 1,250 pounds.

Start by identifying the scaffold’s maximum load capacity. Then, multiply this figure by the desired safety margin percentage. The resulting number is your adjusted load capacity. For example, with a scaffold rated for 2,000 pounds and a 30% safety margin, you’d multiply 2,000 by 1.30, giving you a capacity of 2,600 pounds.

It’s crucial to follow manufacturer guidelines, as some scaffolding systems might have specific safety margin recommendations. Additionally, regularly inspect your scaffold for wear and tear, which can impact its load capacity. By conscientiously applying these calculations and maintenance steps, you’ll ensure a safer working environment and extend the lifespan of your scaffolding equipment.

Understanding load capacity standards is essential for ensuring the safety and stability of scaffolding structures. These standards help you determine how much weight your scaffolding can safely support, preventing accidents and structural failures. To protect workers and comply with regulations, you must be familiar with the guidelines established by governing bodies like OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute).

Here are three critical points to keep in mind when considering load capacity standards: safe work load (SWL), dead load, and live load.

When working with scaffolding, you often encounter mistakes that can compromise safety. Incorrect weight calculations, overloading scaffold platforms, and ignoring manufacturer guidelines are common errors. Let’s address these issues to help you avoid them in your projects.

One of the most common mistakes in scaffolding load capacity is miscalculating the total weight the structure needs to support. This error can lead to serious safety hazards and costly damages. To avoid this, you need to consider all possible loads, not just the obvious ones.

First, make sure you account for the weight of the workers. It’s easy to underestimate this, especially if you’re dealing with a large crew. Each worker adds to the total load, and their movements can create dynamic forces that affect stability.

Second, don’t forget about tools and equipment. These can add significant weight, particularly if you’re using heavy machinery or storing materials on the scaffold. Always include these in your calculations to ensure the structure can handle them.

Lastly, consider environmental factors. Wind, rain, and snow can all add weight and stress to the scaffold. Ignoring these factors can lead to unexpected collapses or shifts in the structure.

Overloading scaffold platforms is a frequent mistake that compromises safety and structural integrity. It might seem like a good idea to load everything you need at once, but doing so can lead to disastrous consequences. Overloading causes the scaffold to become unstable and increases the risk of collapse. To avoid this, always be aware of the load capacity limits and adhere to them strictly.

One common error is underestimating the weight of materials and tools. You might think, “It’s just a few extra bricks,” but those few extras add significant weight. Also, consider the combined weight of workers and their equipment. Even a couple of extra people can push the load capacity beyond its limit.

Another mistake is uneven weight distribution. Placing all the heavy materials on one side of the platform creates imbalance, increasing the risk of tipping. Always distribute weight as evenly as possible to maintain stability.

Lastly, don’t overlook environmental factors like wind or rain. These can add stress to an already overloaded scaffold, making it even more prone to failure under a live load. Always account for these variables to ensure a safe working environment.

Ignoring manufacturer guidelines is a critical mistake that can jeopardize the safety and effectiveness of your scaffolding. These guidelines are meticulously crafted to ensure that the scaffolding can handle specified loads and conditions. When you ignore them, you’re not only risking structural integrity but also the safety of everyone on the site.

First, let’s discuss the consequences of disregarding these guidelines:

Accurately calculating the tools and equipment load is essential to ensure the scaffolding’s stability and safety. When you’re setting up scaffolding, you can’t just think about the weight of the workers; the tools and equipment they bring along play a huge role too, contributing to both the dead load and live load. Failing to account for the additional load can lead to hazardous situations, making your scaffolding structure prone to collapse.

First, take an inventory of all the tools and equipment that will be used on the scaffolding. This includes hand tools, power tools, materials, and even storage boxes. Each item contributes to the overall load, so it’s crucial to be thorough. Weigh each item if you can, or refer to the manufacturer’s specifications for their weights.

Next, consider the distribution of these items. It’s not just the total weight that matters, but also where it’s placed. Unevenly distributed loads can create imbalances, making the scaffolding less stable. Ensure that heavy items are placed closest to the scaffolding’s support structure to minimize tipping risks.

Using tool belts, toolboxes, and organized storage can help manage the distribution effectively, reducing live load on the scaffolding. You should also regularly monitor and adjust the load as work progresses. Sometimes, workers might bring additional tools or equipment onto the scaffolding, and these small increments can add up quickly.

Lastly, always refer to the scaffolding’s load rating provided by the manufacturer. This rating includes both static and dynamic loads. Static loads are the constant weights placed on the scaffolding, while dynamic loads account for the movement and activity of workers and tools. By keeping a meticulous account of these factors, you can ensure a safer working environment.

Ensuring worker safety on scaffolding involves a combination of proper training, equipment checks, and adherence to safety protocols. You can’t afford to overlook any of these elements if you want to maintain a safe working environment. First, make sure everyone who steps onto the scaffolding has received adequate training. Untrained workers are more likely to make mistakes that could lead to accidents. Training should cover everything from how to properly set up the scaffolding to understanding load limits and emergency procedures.

Next, don’t ignore the importance of equipment checks. Regularly examining the scaffolding for any signs of wear and tear can prevent accidents before they happen. Look for cracks, rust, or any other issues that might compromise the structure. If you find any problems, address them immediately before allowing anyone to use the scaffolding.

Adherence to safety protocols is equally crucial. Everyone on the site should have a clear understanding of the safety measures in place and be committed to following them, especially when it comes to scaffolding safety. This includes wearing appropriate personal protective equipment (PPE), such as helmets, harnesses, and non-slip footwear. Also, make sure that the scaffolding is equipped with guardrails and toe boards to prevent falls.

Here are some key points to keep in mind for worker safety:

Regular inspections are a critical step in maintaining the integrity and safety of your scaffolding system. You can’t afford to overlook this aspect because it ensures that any potential issues are identified and addressed before they become serious problems. Regular checks help in spotting wear and tear, corrosion, or any physical damage that could compromise the scaffolding’s load capacity.

First, make sure you inspect the scaffolding before each use. Look for any bent, broken, or missing components. Check the stability of the footing and ensure that all locking mechanisms are secure. Don’t forget to examine the planks for cracks or splits that could weaken their ability to support weight.

You should also schedule periodic, more thorough inspections. These can be weekly or bi-weekly, depending on how frequently the scaffolding is used and the environment it’s in. Pay close attention to areas that are under constant stress, like joints and connections. Rust or other signs of deterioration in these areas can be particularly dangerous.

Keep a detailed log of all inspections. Document any issues you find and the steps you took to fix them. This not only helps in maintaining safety but also provides a record that can be crucial if any incidents occur. Having a documented history can demonstrate due diligence and adherence to safety protocols.

Proper training and certification are essential for anyone working with scaffolding to ensure everyone’s safety on the job site. Without the right knowledge, you risk not only your own safety but also the safety of your coworkers. Training provides you with the skills and know-how to handle scaffolding correctly, while certification demonstrates that you’re competent and compliant with regulations.

When you pursue scaffolding training, you should focus on several key areas. The most critical aspects include:

Certification isn’t just a formality; it’s a requirement in many jurisdictions. It ensures you’ve met the minimum standards set by regulatory bodies, such as OSHA in the United States. Without certification, you could face fines, job site shutdowns, or worse—serious injuries.

If you’re responsible for a team, it’s your duty to ensure that every member has the proper training and certification. Investing in this training can save lives and prevent costly accidents. Moreover, a well-trained team is more efficient and confident, leading to smoother project execution.

Absolutely, weather conditions can impact the stability and safety of scaffolding. Rain, wind, and ice can weaken the structure and reduce its load capacity. Always check weather forecasts and ensure scaffolding is secure before use.

Exceeding load capacity can lead to structural failure, risking serious injury or death. You might face legal consequences, fines, and increased liability. It’s crucial to adhere to guidelines to ensure safety for everyone involved.

You’ll need to consult a structural engineer to handle load capacity for atypical designs. They’ll assess the design, materials, and intended usage to ensure safety. Always follow their guidance and local regulations to prevent accidents.

Yes, there are specific guidelines for scaffolding near power lines. You’ve got to maintain minimum clearance distances, ensure proper grounding, and follow OSHA regulations to ensure worker safety. Always consult local codes for additional requirements for scaffold components.

In earthquake-prone areas, scaffolding needs to be resilient and stable. You’ll want to ensure it’s properly anchored and designed to withstand seismic activity, reducing risks and ensuring safety for workers and structures alike.