Phone:

TBA

Physical address:

TBA

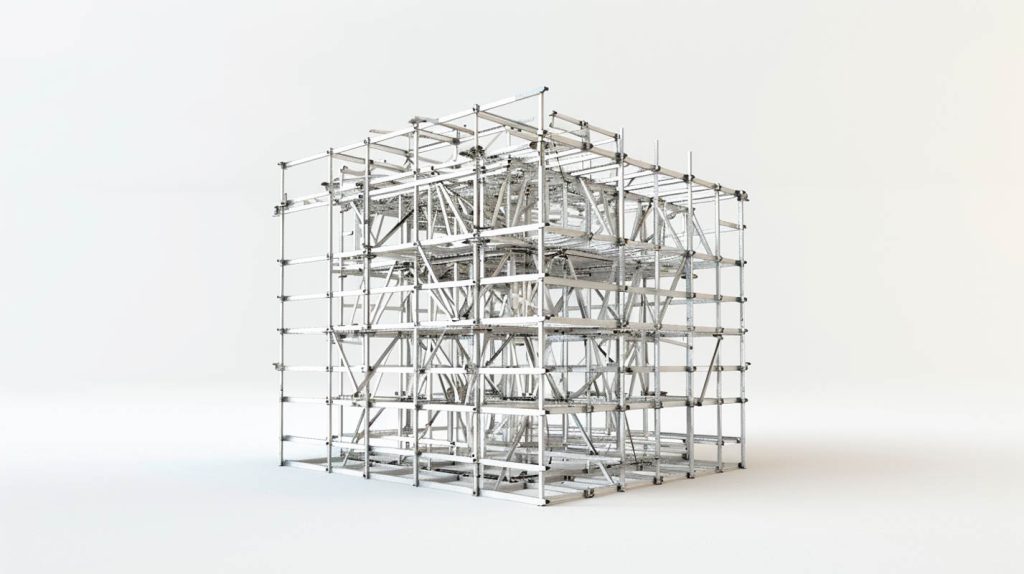

Modular scaffolding systems offer versatility, efficiency, and safety for construction, maintenance, and event applications. They’re easy to assemble, disassemble, and reconfigure using prefabricated components like frames, braces, and couplers. Enhanced safety features include guardrails and non-slip surfaces. Different types like Ringlock, Cuplock, and Kwikstage cater to various project needs. Benefits include faster assembly times, minimal labor, and cost efficiency. Key components ensure support and stability, while their quick assembly and durability make them highly practical. If you’re curious about their wide-ranging uses and cost-saving benefits, you’ll find more detailed information just ahead.

Modular scaffolding is a versatile and efficient system designed to provide safe and flexible access to various work environments. You’ll find it used in construction, maintenance, and even in events where temporary structures are needed. What sets modular scaffolding apart is its ability to be easily assembled, disassembled, and reconfigured to suit different tasks. This adaptability makes it popular among contractors and workers who need to move quickly from one project to another without compromising safety.

Unlike traditional scaffolding, modular systems consist of prefabricated components that fit together seamlessly, similar to ringlock scaffolding or cuplock scaffolding. This means you won’t have to deal with cumbersome poles and planks that require extensive manual labor to set up. Instead, you can snap together pieces with minimal effort, reducing the time and manpower needed for installation. The system’s design allows for various configurations, including straight, circular, or complex structures, making it suitable for a wide range of applications.

One of the biggest advantages you’ll appreciate is the enhanced safety features. Modular scaffolding often includes built-in guardrails, non-slip surfaces, and secure locking mechanisms. These elements ensure that the structure remains stable, minimizing the risk of accidents. Additionally, because it’s designed to be lightweight yet sturdy, you won’t have to worry about it buckling under pressure or harsh weather conditions.

When you’re looking at modular scaffolding systems, it’s crucial to understand the key components that make them work. You’ll primarily deal with frames and braces, which provide structure and stability, and couplers and connectors, which ensure everything fits together securely. Let’s break down these essential parts to see how they contribute to a safe and efficient scaffolding setup.

Frames and braces are the backbone of any modular scaffolding system, providing the necessary support and stability for safe construction work. When you’re setting up a scaffolding system, the frames form the vertical structure, creating the height you need to reach different levels. These frames are usually made of high-strength steel or aluminum, ensuring they can handle heavy loads and resist environmental wear and tear.

Braces, on the other hand, are the horizontal and diagonal components that connect these vertical frames. They play a crucial role in maintaining the rigidity and balance of the entire structure. Without braces, your scaffolding would wobble under pressure, posing serious safety risks. Diagonal braces help distribute weight evenly and prevent the frames from twisting or collapsing, while horizontal braces ensure the frames remain parallel and aligned.

When assembling your scaffolding, make sure each frame and brace is securely connected and properly aligned. Check for any signs of wear or damage before use. Proper installation of frames and braces not only ensures safety but also enhances the efficiency of your construction tasks. Remember, a well-constructed framework is key to a reliable scaffolding system.

Couplers and connectors are essential for securely joining the various components of your modular scaffolding system. They ensure that each part fits together seamlessly and maintains structural integrity. Without these crucial elements, your scaffolding wouldn’t be safe or stable. You’ll find various types of couplers and connectors, each designed for different purposes and load requirements.

Right-angle couplers are the most common, offering a reliable way to connect horizontal and vertical tubes. Swivel couplers provide flexibility, allowing for custom angles. Sleeve couplers are perfect for extending lengths, while putlog couplers are designed for connecting putlogs to ledgers. Finally, girder couplers are used for more demanding applications, such as attaching scaffolding to steel girders. Understanding these components will help you build a safer, more efficient scaffolding system.

There are several types of modular scaffolding systems designed to meet different construction needs and safety requirements. Each type has its unique features, making it suitable for specific tasks and environments. Let’s dive into some of the most common types you’ll encounter.

First up, there’s the Ringlock scaffolding system. This type is known for its versatility and ease of assembly. It uses a rosette with multiple connection points, allowing you to create complex structures that can adapt to various angles and elevations. Ideal for projects that require frequent adjustments, Ringlock is a popular choice for many contractors.

Next, we have the Cuplock system. It’s particularly useful for heavy-duty tasks and large-scale projects. The Cuplock system employs a unique locking mechanism where cups are used to secure the vertical and horizontal components. This design provides a high load-bearing capacity and excellent stability, making it perfect for demanding construction sites.

Kwikstage scaffolding is another type worth mentioning. Known for its simplicity and strength, Kwikstage features a modular design with fewer components, which speeds up the assembly process. It’s great for straightforward projects where time is of the essence, and you need a reliable support system.

H-Frame scaffolding is a go-to for large construction projects like commercial buildings and bridges. Its sturdy frame structure offers excellent support and stability, making it suitable for high-load applications. The H-Frame is easy to erect and dismantle, which saves time and labor costs.

Lastly, the Shoring system is designed specifically for supporting heavy loads. Often used in construction projects like bridges and tunnels, shoring provides temporary support to ensure the safety and stability of structures during construction.

When comparing modular scaffolding to traditional scaffolding, you’ll find some clear advantages. Modular systems offer enhanced safety features that significantly reduce the risk of accidents. Additionally, their quick assembly time means you can get your project up and running much faster.

With modular scaffolding systems, you get enhanced safety features that significantly reduce the risk of accidents compared to traditional scaffolding. One of the key improvements is the use of high-quality, standardized components that fit together seamlessly, ensuring stability and minimizing wobbling. These systems often include built-in guardrails, non-slip surfaces, and secured platforms, which provide an additional layer of protection for workers.

Another advantage is the ease of inspection and maintenance. Modular scaffolding components are designed for quick and straightforward checks, allowing you to spot and address potential safety issues before they become hazardous. This proactive approach helps maintain a safer working environment.

Furthermore, modular scaffolding systems usually come with clear assembly instructions and standardized parts, reducing the likelihood of human error during setup. Traditional scaffolding often relies on various parts that may not always fit perfectly, increasing the risk of instability. With modular systems, you can be confident that each component is designed to work harmoniously with the others, enhancing overall safety.

Incorporating modern safety features like integrated toe boards and secure locking mechanisms, modular scaffolding systems provide a more secure and reliable option. You’ll find that these advancements make a significant difference in keeping your worksite safe.

Alongside enhanced safety features, modular scaffolding systems also offer the advantage of significantly quicker assembly times compared to traditional scaffolding. If you’ve ever been involved in a construction project, you know that time is money. The faster you can get the scaffolding set up, the sooner the work can begin, and the quicker it’s completed, the better for everyone involved.

This table shows just how much of a game-changer modular scaffolding can be. With less labor required, fewer project delays, and higher cost efficiency, it’s clear why many are making the switch. So, next time you’re planning a project, consider how much time and money you could save with modular scaffolding. It’s not just about getting the job done; it’s about doing it smarter and faster.

To ensure worker safety, modular scaffolding systems incorporate guardrails, non-slip surfaces, and secure locking mechanisms. These features are designed to provide a stable and secure environment for anyone working at height. You’ll find that guardrails are crucial in preventing falls, offering an extra layer of protection that’s especially important on high-rise projects. Non-slip surfaces are another essential component, reducing the risk of slips and falls that could lead to serious injuries.

Secure locking mechanisms play a vital role in the overall stability of the scaffolding system. They ensure that all parts of the structure are firmly connected, minimizing any potential wobbling or shifting. When you’re working several stories up, you’ll appreciate the peace of mind that these robust locking systems provide.

Additionally, modular scaffolding often features toe boards. These are small barriers placed at the edge of the platforms to prevent tools or materials from falling, which could injure workers below. You’ll also benefit from the system’s ability to adapt to different environments and project requirements. It’s designed for flexibility, allowing for various configurations while still maintaining a high level of safety.

Moreover, many modular scaffolding systems come with built-in access points like ladders and stairways. These make it easier and safer for workers to move up and down the structure, such as via a stair integrated into the modular scaffold. Safety is further enhanced by the use of high-quality materials that are resistant to wear and tear, ensuring long-term reliability.

Installing a modular scaffolding system requires careful planning and strict adherence to safety guidelines to ensure a secure setup. First, you’ll need to conduct a thorough site assessment. Check for any hazards, and make sure the ground is stable and level. This foundation is crucial because any instability can compromise the entire structure.

Next, gather all necessary components. Modular scaffolding systems are convenient because they come in pre-fabricated sections, such as aluminium kwikally modular scaffold system, which means you’ll have fewer pieces to manage. Ensure you have the correct tools and personal protective equipment (PPE) like gloves, helmets, and harnesses.

Begin the installation by laying out the base plates. These plates distribute the weight and should be placed on firm ground. If the surface is uneven, use adjustable base jacks to level the structure. Connect the vertical standards to the base plates, and then attach the horizontal ledgers. These ledgers will stabilize the vertical standards and form the structure’s basic framework, essential for types of scaffolding systems like ringlock scaffolding.

As you build upwards, it’s essential to secure each level before moving to the next, especially in complex system scaffold setups. Use diagonal braces to add lateral stability, and make sure all connections are locked and secure. Install the platforms, ensuring they’re properly placed and locked in. These platforms will serve as the working surface.

Guardrails and toe boards should be installed at each level to prevent falls and injuries. Double-check each connection, and make sure the scaffolding is plumb and level.

Once you’ve mastered the installation process, modular scaffolding systems become invaluable for various construction applications. Whether you’re working on a towering skyscraper or a simple home renovation, the versatility and adaptability of these systems make your job significantly easier. Let’s dive into some specific ways modular scaffolding systems can transform your construction projects.

First, they offer exceptional support for high-rise buildings. When you’re dealing with structures that reach the sky, safety and stability are paramount. Modular scaffolds provide a robust framework, ensuring that workers can perform their tasks without fear of collapse or instability.

Second, they are perfect for complex architectural designs. Modern buildings often feature intricate shapes and unique angles. Traditional scaffolding can struggle to adapt to these unconventional designs, but modular systems can be configured to fit any structure, no matter how unusual.

Finally, they are ideal for restoration projects. Older buildings require delicate handling and specialized access points. Modular scaffolding allows you to create custom configurations that won’t damage the existing structure while providing the access you need to carry out meticulous restoration work.

Consider the following emotional benefits:

How can modular scaffolding systems save you money on your construction projects without compromising quality? To start with, modular scaffolding is designed for quick assembly and disassembly. This saves you significant labor costs because your crew spends less time setting up and tearing down the scaffolding. Fewer labor hours mean lower expenses, allowing you to allocate your budget to other critical areas of the project.

Another cost-saving aspect is the flexibility and reusability of modular scaffolding systems. Traditional scaffolding often requires custom solutions, which can be both time-consuming and expensive. Modular systems, on the other hand, are highly versatile and can be adapted to various project requirements. This adaptability means you won’t need to invest in different types of scaffolding for different tasks, reducing your overall equipment costs.

Additionally, modular scaffolding components are generally lighter and easier to transport compared to traditional options. Reduced transportation costs translate directly into savings. You’ll also experience fewer delays, which can be costly in terms of project timelines and labor, particularly mitigated by efficient system scaffold solutions.

Durability is another factor to consider. Modular scaffolding systems are built to last, often from high-quality materials that withstand harsh conditions. Investing in a durable system means fewer replacements and repairs, contributing to long-term cost savings.

Selecting the right modular scaffolding system is crucial to ensuring your construction project runs smoothly and efficiently, with options like kwikstage scaffold systems and cuplock scaffolding. Your choice can significantly impact safety, productivity, and overall project costs. With so many options available, it’s essential to consider your specific needs and project requirements.

First, think about the type of work you’re doing. Different projects demand different scaffolding capabilities. Are you working on a high-rise building, a bridge, or a more modest residential property? Each scenario requires distinct scaffolding features and capacities, whether you’re using frame scaffolding or ringlock scaffolding.

Next, consider the ease of assembly and disassembly. Time is money in the construction industry, and a modular system that can be quickly erected and taken down will save you both. Opt for a system that’s user-friendly and doesn’t require specialized training for your crew.

Lastly, assess the quality and durability of the scaffolding materials. You want a system that can withstand harsh weather conditions and heavy use without compromising safety. Investing in high-quality materials may have a higher upfront cost but will save you money in the long run by reducing maintenance and replacement expenses.

Here are some emotional triggers to guide your decision:

Choosing the right modular scaffolding system isn’t just a logistical decision; it’s an investment in your project’s success and your team’s well-being, with options including various types of scaffolding systems. Take the time to evaluate your options carefully to ensure you select the best type of system for your specific needs.

You might find project timelines significantly improved. They allow for faster assembly and disassembly, reducing labor costs and downtime. Additionally, they’re adaptable to various structures, which means fewer delays and more efficient progress on-site.

Yes, you can customize them for unique architectural designs. Modular systems are versatile, allowing adjustments to fit complex structures. This flexibility ensures safety and efficiency, no matter how intricate the building’s design is.

You’ll need to inspect joints, bolts, and connections regularly. Check for wear and tear on all parts, and ensure cleanliness to prevent buildup. It’s essential to follow the manufacturer’s guidelines for periodic maintenance and safety checks.

You’ll find these systems adaptable to various weather conditions. They’re designed with materials that resist corrosion and withstand extreme temperatures. Make sure to secure and inspect them regularly, ensuring stability and safety in any weather.

Yes, there are environmental benefits, particularly when using lightweight solutions like an aluminium kwikally modular scaffold system. You’ll find they reduce waste due to their reusability. They also minimize the need for new materials, lessening the environmental footprint. Plus, they’re easier to transport, lowering fuel consumption, which is a benefit especially noted with aluminium kwikally modular scaffold system.