Phone:

TBA

Physical address:

TBA

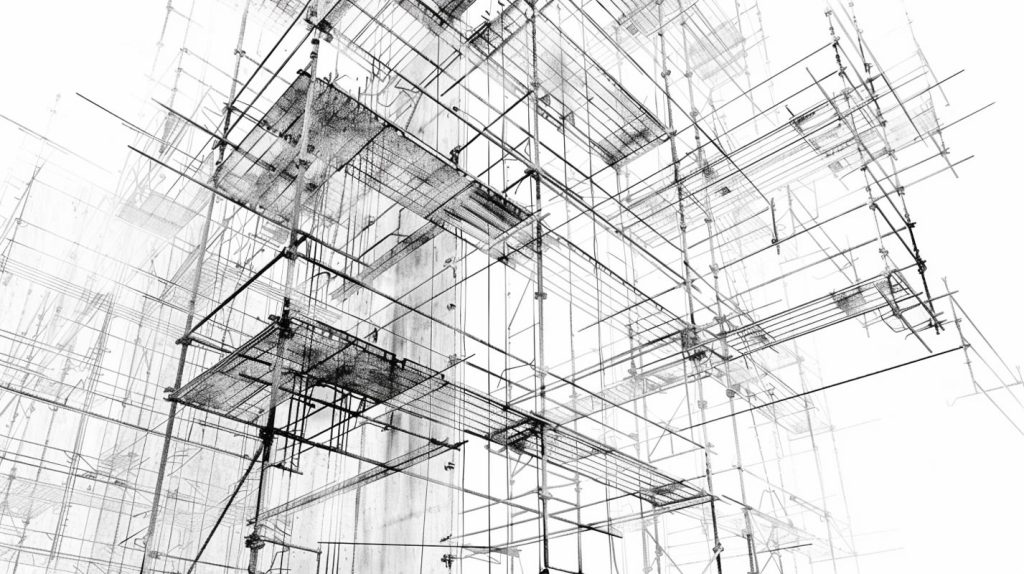

Scaffolding Design Principles – When designing scaffolding, you need to start with a solid base on level ground for stability. Ensure it’s secured to a permanent structure and use diagonal braces for added strength. Always calculate the total load and ensure the scaffolding can support at least four times the maximum intended load. Regularly inspect for damage. Material choice matters: steel for strength, aluminum for lightness, and wood for cost savings. Safety is critical—comply with OSHA standards, install guardrails, and anchor the scaffolding to prevent tipping. Modular and standardized parts can make setup quicker and more efficient. Learn more to ensure your project’s success. Go back to Scaffold for Hire Home Page.

When it comes to scaffolding design, ensuring stability and balance is crucial for both safety and functionality. You can’t afford to overlook these factors, as they form the foundation for a secure working environment. First, you’ve got to start with a solid base. This involves setting the scaffolding on a level surface, free of debris and loose materials. If the ground isn’t level, you should use adjustable base plates or screw jacks to compensate, ensuring the structure remains stable.

Next, you’ll need to consider the scaffolding’s height-to-base ratio. As a general rule, the height should not exceed four times the minimum base width. This ratio helps maintain balance and prevents tipping. Don’t forget to properly secure the scaffolding to a permanent structure if it’s going to be more than a few stories high. Ties and braces are essential for this, providing additional stability and preventing swaying.

Bracing is another key element. Diagonal braces should be installed at regular intervals to reinforce the structure and maintain its integrity. These braces help distribute the load evenly, reducing stress on individual components. You should also make sure that all connections are tight and secure to maintain the integrity of the scaffolding system. Loose fittings can compromise the entire system, leading to instability and risking the integrity of the structure.

Lastly, always inspect the scaffolding before use to ensure integrity and safety. Check for any signs of wear and tear, such as rust or cracks, and replace damaged parts immediately. Regular maintenance is your best defense against unexpected failures. By paying close attention to these details, you’ll create a safer, more reliable scaffolding system that stands up to the demands of any construction project.

While stability and balance form the backbone of a safe scaffolding system, understanding and managing load capacity is equally vital to prevent structural failures during the design process. You can’t overlook how much weight your scaffolding will bear, including workers, equipment, and materials. Exceeding load capacity can lead to catastrophic consequences, endangering everyone on site.

Firstly, you need to calculate the total load that the scaffolding will support. This includes the live load (workers and tools) and the dead load (the scaffolding structure itself). Always factor in a safety margin; it’s better to overestimate than to risk underestimating. Most standards recommend that scaffolding should support at least four times the maximum intended load.

Next, distribute the load evenly. Concentrated loads can create weak points, increasing the risk of failure. Think about how workers and materials will move across the structure. Ensure that platforms are wide enough and properly braced to handle dynamic loads, which change as workers move around.

Regular inspections are another crucial aspect. Even if you’ve calculated the load capacity accurately, wear and tear can compromise the structure. Look for any signs of damage or instability, and don’t hesitate to make immediate repairs. It’s also essential to train your team to recognize potential overload conditions.

Lastly, don’t forget to consider environmental factors in order to achieve a successful and durable scaffold erection. Wind, rain, and even temperature changes can affect the load capacity of your scaffolding. Make sure to account for these variables in your planning. By paying close attention to load capacity, you’ll ensure that your scaffolding remains safe, sturdy, and reliable throughout your project.

Choosing the right materials for your scaffolding is crucial to ensuring both safety and durability. The material you select can significantly impact the scaffolding’s performance, cost, and ease of assembly. You’ll need to consider factors like weight, strength, and resistance to environmental conditions. Typically, scaffolding materials include steel, aluminum, and sometimes wood. Let’s break down the key considerations for each.

Steel is a popular choice due to its strength and durability. It can support heavy loads and withstand harsh weather conditions. However, steel is heavy, making it harder to transport and assemble, thus impacting the ease of installation. If you choose steel, ensure it’s galvanized to prevent rust.

Aluminum, on the other hand, is lightweight and easy to handle. It doesn’t rust, which makes it ideal for projects in humid or coastal areas to maintain structural integrity. The trade-off is that aluminum isn’t as strong as steel, so it may not be suitable for very heavy loads.

Wood is less common but still used in some scaffolding applications. It’s easy to work with and relatively inexpensive. However, wood is susceptible to rot and damage from insects, so it requires regular maintenance.

When selecting your scaffolding material, consider the following:

After selecting the right materials, it’s equally important to ensure your scaffolding complies with all necessary safety regulations. You can’t afford to overlook this aspect because non-compliance can lead to severe consequences, including accidents, injuries, and legal penalties. Familiarize yourself with the Occupational Safety and Health Administration (OSHA) standards or any other local regulations that apply to your area.

First, make sure your scaffolding is designed to support its intended load. This includes the weight of workers, tools, and materials. Overloading can cause structural failure, leading to catastrophic results. Always adhere to the manufacturer’s guidelines and never exceed the recommended load limits.

Next, focus on stability. Scaffolding must be placed on a solid, level foundation. If the ground is uneven, use base plates or mud sills to distribute the load evenly. Additionally, scaffold towers should be anchored or tied to the building at regular intervals to prevent tipping.

Guardrails are another critical safety feature. Install guardrails, midrails, and toeboards on all open sides and ends of the scaffolding to prevent falls. This is especially crucial if the scaffolding is more than 10 feet above the ground. Ensure that these guardrails are securely attached and can withstand the force of a fall.

To maximize design efficiency, you should focus on creating a scaffolding system that’s both easy to assemble and adaptable to various project needs. The goal is to reduce labor time and costs while ensuring the system can be modified to fit different structures and heights. Efficient design isn’t just about speed; it’s also about making sure the scaffolding is versatile and durable.

One key strategy is to use modular components. These allow for quick setup and teardown, and they can be easily reconfigured for different tasks. Lightweight materials are another consideration, as they can significantly reduce the physical strain on your crew and speed up the assembly process.

Here are some important factors to keep in mind to enhance design efficiency during the design process:

Weather conditions can significantly impact scaffold performance. Rain can make surfaces slippery, wind can destabilize structures, and extreme temperatures can affect material strength. You must always consider these factors when using scaffolding.

You’ve got to regularly inspect scaffolding for any wear and tear, clean it to prevent buildup, tighten bolts, and replace damaged parts. Keep an eye out for rust, and ensure everything’s stable and secure before use.

Yes, there are specific training programs for scaffold assembly, which cover essential skills and information. You’ll learn safety protocols, proper techniques, and regulatory standards. These programs ensure you can assemble scaffolding correctly and safely, reducing risks on construction sites.

To improve worker productivity, ensure scaffolds are easy to assemble and adjust during the installation process. Prioritize safety and stability, and incorporate platforms that allow easy access to tools and materials. Efficient design minimizes downtime and boosts overall efficiency.

You’ve got to consider the materials used, their recyclability, and the impact on the local ecosystem. Make sure the design minimizes waste and energy consumption. It’s essential to balance safety, productivity, and environmental responsibility.