Phone:

TBA

Physical address:

TBA

Mastering scaffold erection techniques is key for safety and efficiency. Always follow the manufacturer’s guidelines and check the ground for a solid foundation. Use base plates for stability and anchor the scaffold securely to prevent tipping. Essential tools like wrenches and levels ensure proper alignment. Don’t skip safety gear—hard hats, harnesses, and non-slip boots are a must. Inspect all components for damage regularly, especially after bad weather. Guardrails and toe boards are vital for preventing falls. Following these steps keeps the scaffold secure and workers safe. Stick around to discover all the critical details you need to know. Go back to Scaffold for Hire Home Page.

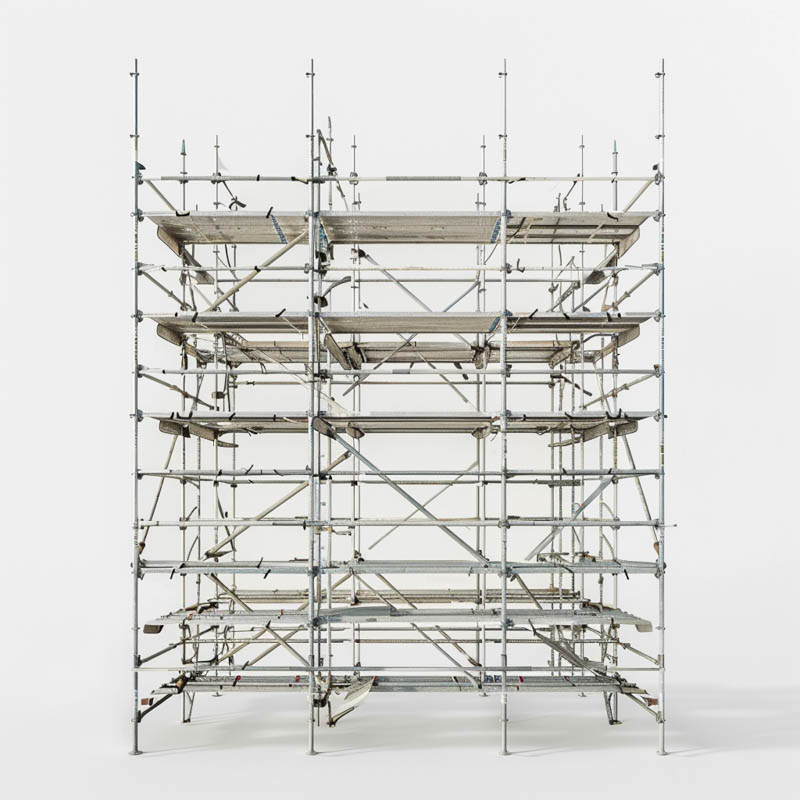

There are several types of scaffolding you’ll encounter on construction sites, each suited to different tasks and environments. The most common ones include supported scaffolding, suspended scaffolding, and rolling scaffolding, which all serve as types of work platforms. Knowing which type to use is crucial for efficiency and safety.

Supported scaffolding is the most prevalent. It consists of platforms supported by rigid, load-bearing legs. You’ll often see this type on the ground level, extending upwards as needed. It’s ideal for tasks that require a stable base, like bricklaying or painting exterior walls. The frames can be stacked and connected, allowing for various heights and configurations.

Suspended scaffolding, on the other hand, hangs from an overhead structure using ropes or cables. You’ll find this type in high-rise building projects where it’s impractical to build from the ground up. Window washers often use suspended scaffolding to access difficult-to-reach areas. This type can be adjusted to different heights, making it versatile for various tasks.

Rolling scaffolding is another popular choice, often providing a mobile work platform. It’s essentially like supported scaffolding but with wheels at the base, allowing you to move it easily across flat surfaces. This type is perfect for tasks like electrical work or interior wall painting, where you need to frequently reposition the scaffold.

Each type of scaffolding has its own set of advantages and limitations. Choosing the right one depends on the specific needs of your project, the height you need to reach, and the nature of the work you’ll be doing. Understanding these differences will help you select the most appropriate scaffolding, ensuring both efficiency and safety on the job site.

When it comes to erecting scaffolding safely and efficiently, you’ll need a well-stocked toolkit with essential items like wrenches, levels, and safety harnesses. These tools are the backbone of any successful scaffold build, ensuring that everything is not only secure but also aligned perfectly.

First up, wrenches are indispensable. You’ll use them to tighten bolts and secure connections. Whether it’s a ratcheting wrench or a basic adjustable one, having a reliable wrench is crucial for making sure your scaffolding is stable and secure, especially when installing or removing a ladder.

Next, you’ll need a level. This tool helps you confirm that each part of your scaffold is perfectly horizontal or vertical, ensuring safe footing. Levels come in various sizes, but a standard 24-inch level should cover most of your needs to ensure the scaffolding is properly aligned during erecting and dismantling. It’s essential for avoiding any tilts or slants that could compromise the structure’s stability.

Lastly, don’t forget the safety harness. Scaffolding often involves working at significant heights, and a fall could have serious consequences. A safety harness, complete with a fall arrest system, ensures that you stay secure while you’re up there.

Here’s a quick summary to help you visualize these essentials:

Having these three items in your toolkit sets the foundation for a safe and efficient scaffold erection process. By making sure you’re equipped with these essentials, you’ll be well-prepared to tackle the challenges that come with building scaffolding.

Adhering to safety guidelines is crucial to preventing accidents and ensuring a secure working environment while erecting scaffolding. You must always prioritize safety to protect yourself and your coworkers. Start by wearing the appropriate personal protective equipment (PPE), such as hard hats, non-slip boots, and harnesses before starting to erecting and dismantling the scaffold. Make sure that the scaffolding components are in good condition and free of defects. Inspect every piece before use to avoid any structural failures.

Stability is another critical aspect. Make sure the ground where you’re erecting the scaffold is level and can support the weight of the scaffolding and the workers. Use base plates and mud sills to distribute the weight evenly. Guardrails and toe boards should be installed on all open sides to prevent falls and injuries.

Training is equally important. All workers involved in erecting scaffolding should be trained on the proper techniques and safety protocols. This includes understanding load capacities and recognizing potential hazards.

To ensure a safe and efficient scaffold assembly, follow these step-by-step instructions meticulously. First, gather all necessary components and inspect them for any damage. This ensures that every piece is in optimal condition and ready for use. Start by laying out the base plates on level ground and adjusting them as needed to create a stable foundation.

Continue building upwards by repeating these steps, adding additional frames, braces, platforms, and guardrails as needed. Always double-check connections at every stage to ensure they’re secure.

Despite careful assembly, there are common mistakes that can jeopardize scaffold safety and efficiency. One frequent error is failing to secure the base properly. If the scaffold isn’t stable from the ground up, it’s a disaster waiting to happen. Always ensure the base plates and mud sills are correctly positioned and leveled.

Another mistake is overloading the scaffold. Each scaffold has a maximum load capacity, and exceeding this can lead to catastrophic failure. You should always account for the weight of workers, tools, and materials. Stick to the manufacturer’s guidelines to avoid this pitfall.

Improper bracing is another common issue. Without adequate bracing, the scaffold can sway or collapse, especially under wind or load pressure. Cross braces and horizontal braces need to be installed as per the recommended configuration to ensure stability, inspected by a competent person.

Neglecting guardrails and toe boards is also a critical mistake. These components are essential for preventing falls and securing tools and materials. Skipping their installation can lead to severe accidents and injuries. Always make sure guardrails and toe boards are in place and properly secured.

Additionally, not following the manufacturer’s assembly instructions can cause significant problems. Each scaffold system can have unique requirements. Ignoring these guidelines can compromise the structural integrity and safety of the scaffold. Always refer to the instruction manual during assembly.

Lastly, using damaged or incompatible components can be extremely hazardous during both erecting and dismantling the scaffold. Components must be inspected and verified for compatibility with the scaffold system in use. Never mix parts from different manufacturers unless explicitly stated as safe to do so.

When it comes to scaffold safety, you can’t skip regular inspections and maintenance. Make sure to check the integrity of all components, including the footing, to prevent accidents. Consistent safety checks ensure that your scaffolding remains secure and reliable.

Regular safety checks ensure that scaffolding structures remain secure and reliable throughout their use. When you’re responsible for scaffolding, it’s crucial to conduct these checks regularly to prevent accidents and ensure worker safety. Here’s a simple guide to help you visualize the process:

Once the regular safety checks are complete, it’s time to focus on verifying the integrity of each scaffold component through meticulous inspection and maintenance. Start by examining all metal parts for signs of corrosion, cracks, or deformation. Don’t overlook welds and joints, as these spots are particularly vulnerable to stress and wear. Ensure that all locking mechanisms, such as clips and pins, are functioning properly and securely fastened.

Next, inspect wooden planks for splits, knots, or rot. Wooden components should be free from paint or treatment that could conceal damage, ensuring a clear inspection by the competent person. If any plank, which is part of the scaffold, shows signs of weakness, replace it immediately to prevent accidents.

Regularly lubricate moving parts of the scaffold to keep them operating smoothly and to prevent rust. Also, monitor the scaffold’s base for stability issues. Any settling or shifting ground can undermine the entire structure’s integrity.

Document each inspection and maintenance activity. Keeping detailed records helps track component lifespan and identify recurring issues. Finally, ensure that all personnel are trained to spot potential problems and report them promptly. A proactive approach to component integrity verification dramatically reduces the risk of scaffold failure, ensuring a safer work environment.

You’ll need leveling jacks and base plates to stabilize scaffolding on uneven terrain. Adjust each leg individually to match the ground’s slope, ensuring the structure remains secure and balanced throughout its use.

When erecting scaffolding, you’ve got to consider the impact on local ecosystems, noise pollution, and waste management. Ensuring materials are eco-friendly and minimizing disturbance to wildlife are crucial for environmentally responsible construction.

Weather conditions can significantly impact scaffold stability. High winds, rain, and snow can weaken the structure or cause it to become slippery. You’ve got to ensure all safety measures are in place to prevent accidents.

Yes, scaffolding can be used for non-construction purposes. You might see it in events for stage setups, in art installations, or for temporary structures. It’s incredibly versatile beyond just construction sites.

You need formal training and certification to ensure safety and compliance with regulations. It often includes OSHA standards, hazard recognition, proper use of personal protective equipment, and hands-on practice. Ongoing education is also crucial.