Phone:

TBA

Physical address:

TBA

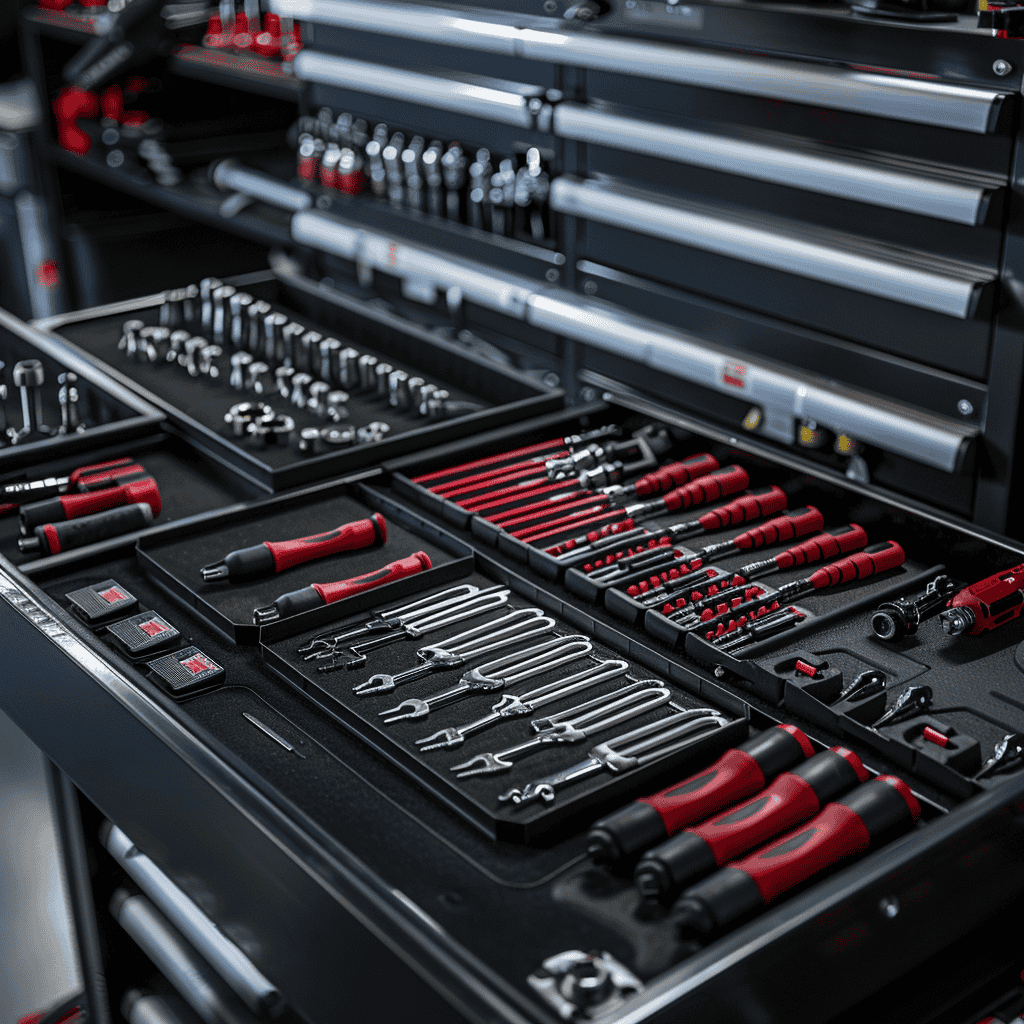

When it comes to assembling scaffolding safely and efficiently, you’ll need the right tools. Ratchet spanners are key for tightening bolts quickly. Scaffold wrenches help with fasteners, offering dual-head designs for versatility. Leveling devices like screw jacks ensure your setup is stable. Don’t forget safety harnesses to protect against falls, and guardrail systems to keep edges secure, much like how careful assembly scaffolding protects the integrity of a genome. Each tool has unique features that make your job easier and safer. Love details? There’s even more to discover!

When you’re assembling scaffolding, ratchet spanners are essential for efficiently tightening and loosening bolts. These tools save you a significant amount of time and effort compared to traditional spanners. The ratchet mechanism allows for continuous motion without needing to remove and reposition the spanner after each turn. This feature is particularly useful when you’re working in tight spaces or awkward angles where a full rotation isn’t possible.

Ratchet spanners, a vital scaffolding tool, come in various sizes to fit different bolt heads, ensuring you always have the right tool for the job. The most commonly used ones in scaffolding are usually metric sizes, but it’s always good to have a mix. Some models even come with a switch that allows you to change the direction of the ratcheting mechanism, making it versatile for both tightening and loosening.

Durability is another key aspect to consider. Look for ratchet spanners made from high-quality materials like chrome vanadium steel. This material is known for its strength and resistance to wear and tear, ensuring your tools last longer even under tough working conditions, much like a well-assembled reference genome stands the test of time. The handle should also provide a good grip, often featuring ergonomic designs and non-slip materials to reduce hand fatigue.

Having a set of reliable ratchet spanners can make your scaffold assembly process much smoother and more efficient. They help you maintain a steady workflow, reduce the risk of hand injuries, and ensure that all joints and connections are securely fastened. So, next time you’re gearing up for a scaffolding project, make sure your toolkit includes a set of high-quality ratchet spanners.

For assembling scaffolding, scaffold wrenches are indispensable tools that offer both versatility and efficiency. You need a tool that can handle the various bolts and nuts you’ll encounter on the job. Scaffold wrenches come in different shapes and sizes, but their primary function remains the same: to tighten or loosen fasteners quickly and securely.

One of the key features you’ll appreciate is the dual-head design. Most scaffold wrenches have two different-sized sockets, allowing you to switch between different fasteners without changing tools. This saves you time and reduces the hassle of carrying multiple wrenches.

Another aspect to consider is the handle design. Scaffold wrenches often come with ergonomic handles, making them comfortable to use for extended periods. Some models even have a ratcheting mechanism, which speeds up the process by letting you turn the wrench back and forth without lifting it off the nut or bolt. This can be a real time-saver, especially when you’re working on large projects.

Durability is another crucial factor. Scaffold wrenches are typically made from high-quality steel, ensuring they can withstand the rigors of the job site. You don’t want a tool that bends or breaks under pressure, and a good scaffold wrench will hold up even in tough conditions, much like long reads support robust genome assemblies.

Lastly, many scaffold wrenches feature a tethering point, which is essential for safety, similar to how tethering contigs is crucial in assembly scaffolding. If you’re working at height, you can attach the wrench to your belt or harness to prevent it from falling and causing injuries below. Go back to Scaffold for Hire Home Page.

Leveling devices are crucial for ensuring that your scaffolding is stable and safe to use. Without proper leveling, you risk creating an unstable structure that could lead to accidents and injuries. The primary purpose of these devices is to make sure your scaffold sits evenly on the ground, compensating for any uneven surfaces.

The most common leveling devices you’ll encounter are adjustable base plates and screw jacks. These tools allow you to fine-tune the height of each scaffold leg, ensuring that the entire structure is level. Screw jacks, in particular, are incredibly useful because they offer precise adjustments, which is essential for achieving a perfectly level scaffold. To use a screw jack, you’ll simply turn the handle to raise or lower the scaffold leg until it’s level with the others.

Bubble levels are another essential tool in this process. By placing a bubble level on the scaffold platform or horizontal members, you can easily see if the structure is level. If the bubble isn’t centered, you know that adjustments are needed. Some advanced leveling devices even come with digital readouts, providing even more accuracy.

Don’t forget to check the leveling periodically as you work. Weight distribution and movement can shift the scaffold, making it necessary to re-level, similar to how adjustments are needed during assembly using long reads. It’s a good practice to inspect the leveling at the start of each day and after any significant changes in load or position.

Safety harnesses are essential for protecting workers from falls while working on scaffolding. When you’re up high, a slip or misstep can lead to severe injuries or worse. That’s where a safety harness comes in. It’s not just a piece of gear; it’s a lifeline that keeps you secure and gives you peace of mind while you’re focused on the job, much like a well-constructed draft genome offers security in genetic research.

To ensure maximum protection, you need to choose the right harness. Look for one that’s comfortable, easy to adjust, and meets all safety standards. A good harness distributes the force of a fall across your body, minimizing injury. Always check for proper certification to ensure it meets industry standards and regulations.

When you’re putting on your harness, make sure it’s snug but not too tight. The straps should be free of twists and tangles. Double-check all buckles and adjustments before you start working. It’s also crucial to inspect your harness regularly for signs of wear and tear. Frayed straps or damaged buckles can compromise your safety.

Connecting your harness to a secure anchor point is just as important as the harness itself. The anchor point should be strong enough to support the forces exerted in a fall. Use a lanyard or lifeline that’s compatible with your harness and rated for the specific work environment.

When you’re working on scaffolding, guardrail systems are your first line of defense against falls. They provide a physical barrier that can prevent you from accidentally stepping off the edge, similar to how a draft genome offers an initial barrier in genetic analysis. It’s crucial to understand the components and proper installation of these systems to ensure your safety on the job.

Guardrail systems typically consist of three main parts: top rails, midrails, and toeboards. Each component serves a specific purpose and must be installed correctly to be effective. Here’s a breakdown of what you need to know:

When setting up a scaffold, always prioritize the installation of guardrail systems. They aren’t just regulatory requirements; they play a key role in your safety. By understanding and implementing these components correctly, you can significantly reduce the risk of falls and create a safer work environment for yourself and your team.

To ensure safety, you should regularly inspect scaffolds for damage, clean and store components properly, tighten any loose parts, and follow manufacturer guidelines. Always train your team on maintenance procedures to prevent accidents.

To transport scaffold materials safely, you’ve got to secure them properly. Use tie-down straps and ensure the load is balanced, much like how you would ensure balance in a genome assembly. Avoid overloading vehicles and always follow safety regulations to prevent accidents and ensure stability.

To assemble scaffolds safely, you’ll need comprehensive training in hazard recognition, proper use of equipment, and fall protection. OSHA requires that workers complete specific training courses provided by certified professionals to ensure safety and compliance.

You shouldn’t use scaffolds in extreme weather conditions. High winds, heavy rain, or snow can make them unstable and dangerous. Always prioritize safety and check weather forecasts before planning any scaffold-related work.

To calculate a scaffold’s load capacity, you’ll need to consider the scaffold type, materials used, and configuration, much like in de novo genome assembly. Check manufacturer guidelines, ensure even weight distribution, and apply safety factors to avoid overloading and ensure stability.