Phone:

TBA

Physical address:

TBA

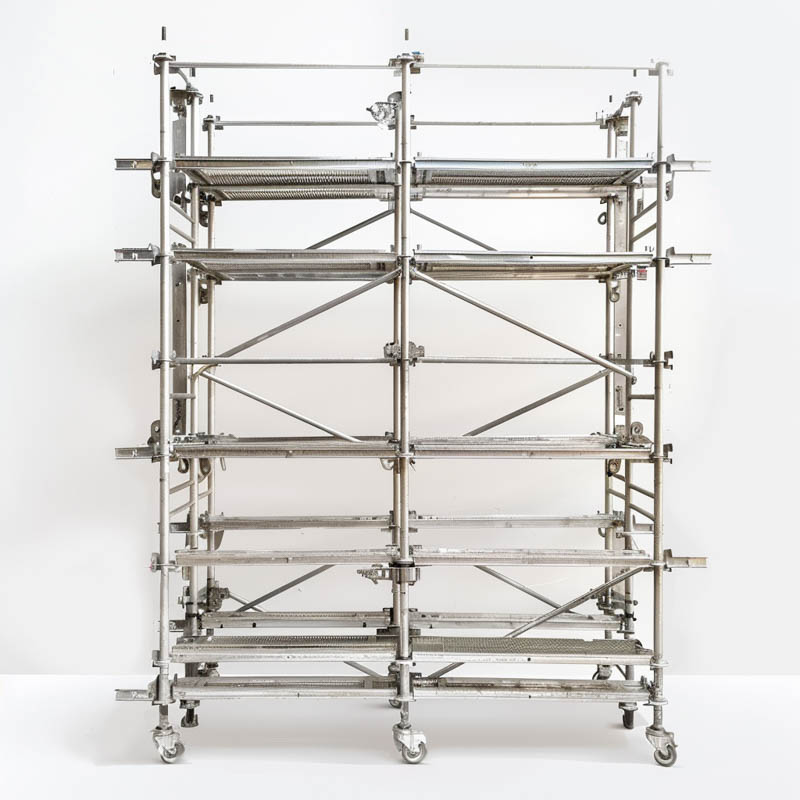

Considering an aluminium mobile scaffold tower? It’s lightweight, making transport and assembly a breeze. Aluminum is also durable, resisting rust and corrosion, perfect for indoor and outdoor tasks. Look for key features like adjustable height, secure locking mechanisms, and a wide base for stability. Always check maximum working height and load capacity to ensure safety. Regular maintenance, like inspecting for damage and cleaning, will keep your scaffold in top shape. To get more insights on choosing the right scaffold and best maintenance practices, continue exploring the detailed information provided.

One of the key benefits of Aluminium Mobile Scaffold Tower is their lightweight nature, making them easy to transport and assemble, which is why they’re popular in cities like Sydney and Melbourne. You’ll find that moving these foldable towers from one job site to another is a breeze. Unlike heavier materials, aluminium doesn’t require much effort or equipment to handle. This ease of transport can save you time and physical strain, allowing you to focus more on the task at hand.

Another advantage is the durability of aluminium. Despite being lightweight, aluminum is incredibly strong and resistant to rust and corrosion. You won’t have to worry about the scaffold deteriorating over time, even when exposed to harsh weather conditions. This longevity means you’ll get more use out of your investment, reducing the need for frequent replacements.

Lastly, aluminium scaffold towers offer remarkable versatility. They’re suitable for both indoor and outdoor projects, providing a stable and reliable platform for a variety of tasks. Whether you’re painting a ceiling or repairing a roof, you’ll appreciate the adaptability these towers offer. Plus, their modular design allows you to adjust the height and configuration to meet the specific requirements of your project.

When choosing an aluminum mobile scaffold tower, it’s crucial to think about height and stability to ensure safety during use. You’ll also want to consider how portable the tower is and how easy it is to assemble. These key features can make a significant difference in your overall experience and efficiency.

Ensuring the aluminium mobile scaffold tower’s height and stability is crucial for both safety and efficiency on any job site. When selecting a scaffold tower, you need to consider the maximum working height it offers. Make sure it meets your project requirements without compromising safety. Typically, these towers provide adjustable heights, allowing you to customize them based on the task at hand.

Stability is another critical factor. A well-designed scaffold tower should have a wide base to prevent tipping over. Look for models with stabilizers or outriggers, which add extra support and balance. Additionally, ensure the tower has secure locking mechanisms for both the wheels and the frame. This prevents any unintended movement while you’re working at height.

You should also check the load capacity. The tower must support not only your weight but also that of your tools and materials. Overloading can compromise stability and increase the risk of accidents.

Lastly, always inspect the scaffold’s components before each use. Tighten any loose bolts and ensure all parts are in good condition. By focusing on these key aspects, you’ll create a safer and more efficient working environment.

While height and stability are paramount, don’t overlook the importance of portability and ease of assembly when choosing an aluminum mobile scaffold tower. You want a tower that’s not only sturdy but also lightweight and easy to move. Look for towers made from high-quality aluminum, which offers a good balance between strength and weight. This ensures you can easily transport it from one job site to another without breaking your back.

Ease of assembly is another critical factor. A scaffold tower that’s complicated to set up can waste valuable time and increase frustration. Opt for models with fewer components and intuitive assembly instructions, particularly when considering delivery options in Australia. Quick-lock mechanisms and snap-on joints can make the process almost effortless. You should be able to set up and dismantle the tower quickly, saving time and labor costs, which is why many hire these scaffolds for short-term projects.

Some Aluminium Mobile Scaffold Tower even come with wheels, adding another layer of convenience. Make sure the wheels are lockable to ensure stability once the tower is in place. By considering both portability and ease of assembly, you’ll ensure your scaffold tower is not just a piece of equipment but a reliable partner on the job site.

To ensure you’re using an aluminium mobile scaffold tower safely, always check that all components are in good condition before assembly. Inspect for any signs of damage or wear, such as bent frames or broken welds. Faulty parts can compromise stability and increase the risk of accidents.

When setting up the scaffold, make sure it’s on a flat, stable surface. Uneven ground can cause the tower to tip over. Always lock the wheels in place once you’ve positioned the scaffold to prevent it from moving unexpectedly. If you’re working on uneven terrain, use adjustable legs to level the scaffold.

Never exceed the weight limit specified by the manufacturer. Overloading can lead to structural failure. Distribute your tools and materials evenly to maintain balance. Additionally, ensure that guardrails are installed and secure to prevent falls.

Always climb the scaffold using the designated ladder frames, not the cross braces. Wear appropriate personal protective equipment, including a hard hat and non-slip footwear. Keep the workspace organized and free from debris to minimize tripping hazards.

Lastly, never move the scaffold while someone is on it. Always ensure all personnel are off the tower before adjusting its position. Following these best practices will help ensure a safe and efficient working environment, whether in Melbourne or Sydney.

When assembling or disassembling your aluminium mobile scaffold tower, you’ll need specific tools and equipment to ensure everything fits together correctly. Before you start, always prioritize safety precautions to prevent accidents. Let’s go over the essential tools and the key safety steps you’ll need to follow.

You’ll need a few essential tools and pieces of equipment to efficiently assemble and disassemble an aluminium mobile scaffold tower. First, make sure you have a sturdy wrench or spanner. This will be crucial for tightening and loosening bolts and nuts. A rubber mallet is also necessary for gently knocking components into place without damaging the aluminium.

Next, you’ll need a set of locking pliers. These accessory tools will help you grip and hold parts securely as you work. A spirit level is indispensable to ensure that your scaffold is perfectly horizontal, which is vital for stability. Don’t forget a tape measure to verify accurate distances and alignments; precise width measurements are crucial.

Additionally, keep a screwdriver set handy, as some Aluminium Mobile Scaffold Towers use screws instead of bolts. Safety gloves are a must for protecting your hands from sharp edges and pinches. While not a tool, having a parts checklist can streamline the process, ensuring you don’t miss any crucial components.

Before starting the assembly or disassembly of an aluminium mobile scaffold tower, ensure you prioritize safety by wearing appropriate personal protective equipment (PPE). This includes a hard hat, safety glasses, gloves, and non-slip footwear. It’s essential to also use a harness if you’re working at significant heights. Neglecting PPE can lead to severe injuries.

Next, inspect the scaffold components for any damage or wear. Don’t use any parts that appear compromised. Ensure the ground where you’ll be assembling the scaffold is level and stable. Uneven or soft ground can cause the scaffold to tip over or collapse.

During assembly, follow the manufacturer’s instructions carefully. Make sure each piece locks securely into place before moving on to the next when assembling your foldable scaffold. Never attempt to force parts together, as this can weaken the structure.

When disassembling the scaffold, work methodically from the top down. Avoid removing lower sections first, as this destabilizes the entire structure. Keep tools and parts organized to prevent tripping hazards.

Regular maintenance and proper care are crucial to ensuring the safety and longevity of your aluminium mobile scaffold tower. First, always inspect the scaffold before each use. Look for any signs of wear, corrosion, or damage to the aluminium components. If you find any issues, don’t use the scaffold until repairs are made.

Keep your scaffold clean by wiping it down regularly. Dirt and debris can cause wear and tear over time. Use mild soap and water to remove any grime, but avoid harsh chemicals that might damage the aluminium.

Lubricate moving parts like casters and joints periodically to ensure smooth operation. Use a non-corrosive lubricant to keep these parts in good working order. It’s also important to check the locking mechanisms to make sure they engage properly.

Store your scaffold in a dry, sheltered area when not in use. Exposure to the elements can lead to corrosion and weaken the structure. If you must leave it outside, cover it with a weather-resistant tarp.

When choosing the right scaffold tower, consider the specific tasks you’ll be performing and the height you need to reach. If you’re painting a ceiling or installing lighting, you’ll need a taller tower compared to tasks like window cleaning or minor repairs. Measure the height of the work area to ensure the scaffold tower provides adequate reach.

Next, think about the environment you’ll be working in. For indoor projects, a lightweight, compact scaffold might be ideal. However, for outdoor jobs, you’ll want a more robust structure that can withstand wind and uneven surfaces. Aluminium scaffold towers are versatile and suitable for both environments due to their durability and lightweight nature.

Weight capacity is another crucial factor. Make sure the scaffold can support not only your weight but also the weight of your tools and materials. Overloading a scaffold can compromise its stability and safety.

Lastly, consider mobility and ease of assembly. If you need to move the scaffold frequently, look for models with lockable wheels and easy-to-assemble parts. This flexibility can save you a lot of time and effort, making your project run more smoothly. Always prioritize safety and compliance with local regulations when making your choice.

The first step in choosing the right scaffold tower is to clearly define the tasks you will be performing and the height you need to reach. Different tasks require different scaffold heights:

Ceiling Painting or Light Installation: These tasks typically require a taller scaffold tower to provide adequate reach.

Window Cleaning or Minor Repairs: For these activities, a shorter tower might suffice.

To ensure you select the right height, measure the work area from the ground to the highest point you need to access. This will help you determine the minimum scaffold height required.

The environment where the scaffold will be used plays a significant role in your decision:

Indoor Projects: For indoor use, a lightweight and compact scaffold tower is often ideal. Aluminium towers are particularly suitable due to their durability and light weight, making them easy to maneuver in confined spaces.

Outdoor Jobs: When working outdoors, you need a more robust scaffold that can withstand wind and uneven surfaces. Aluminium towers are versatile and durable, making them suitable for various outdoor conditions.

It’s crucial to consider the weight capacity of the scaffold tower. Ensure that it can support your weight along with the weight of any tools and materials you’ll be using. Overloading the scaffold can lead to instability and increase the risk of accidents. Always check the manufacturer’s weight capacity specifications and adhere to them strictly.

Ease of movement and assembly can greatly impact the efficiency of your work:

Mobility: If your project requires frequent relocation of the scaffold, opt for models equipped with lockable wheels. This feature allows for easy movement while ensuring stability when the scaffold is in use.

Ease of Assembly: Look for scaffold towers that are easy to assemble and disassemble. This will save you significant time and effort, particularly if you need to move and reassemble the scaffold multiple times during a project. Go back to Scaffold for Hire home Page.